The transport of laboratory samples, pharmaceuticals and other temperature-sensitive goods, requires containers that enable shipment at specific temperatures and under defined climatic conditions. Temperatures of -40°C may even have to be guaranteed for worldwide shipment with all potential interruptions.

Nowadays, cryogenic samples are usually shipped with dry ice or liquid nitrogen as coolant. The transport containers are usually made of polystyrene – only rarely do they have high-quality insulation. Both variants release large quantities of harmful gases (CO2 or N2) – and even the insulation containers often fail to meet requirements.

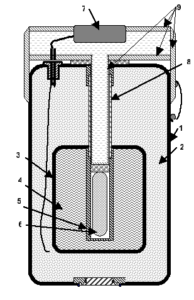

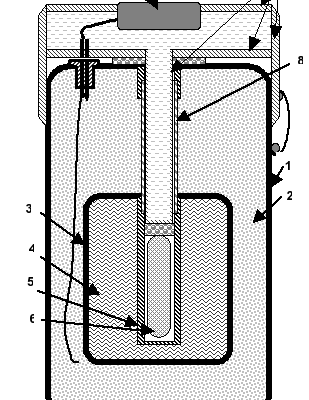

KryoSafe® offers a genuine alternative in the form of supported vacuum insulation. The closed latent heat storage tanks are encased in insulation that cools what has to be kept cooled for a long period. All components are hermetically sealed, thus eliminating environmental damage or any negative effects on the goods.

Due to the overall construction of several nested, stable stainless steel containers, even contaminated or otherwise samples and substances that may be harmful to the environment or human health can be transported safely.